Product Description

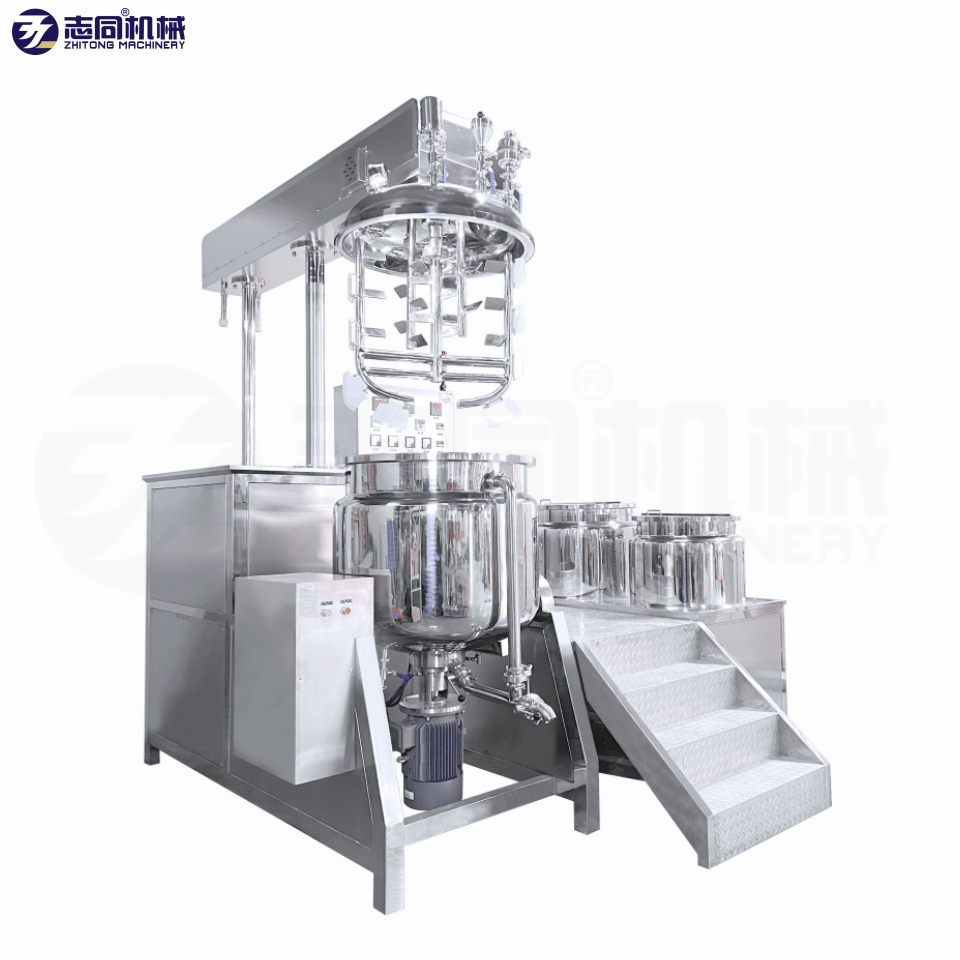

1. The three-layer stainless steel pot body is the middle interlayer, the heat insulation layer, and the material contact part is 316L, the middle layer is the heating layer 304 stainless steel, and the heat insulation layer is the heat preservation layer 304 stainless steel.

2. The structure design of the whole machine is reasonable, the selection of materials is excellent, and the best emulsification system.

3. Stepless speed regulation, high speed up to 6000rpm, high for your cutting line speed of 66m/s.

4. Homogeneous stirring and paddle stirring can be used separately or at the same time. Material dispersion, homogenization, emulsification, mixing, and mixing can be completed in a short time.

5. The three-layer stainless steel pot body is the middle interlayer, the heat insulation layer, and the material contact part is 316L, the middle layer is the heating layer 304 stainless steel, and the heat insulation layer is the heat preservation layer 304 stainless steel.

6. The structure design of the whole machine is reasonable, the selection of materials is excellent, and the best emulsification system.

6. Stepless speed regulation, high speed up to 6000rpm, high for your cutting line speed of 66m/s.

7. Meet your different working environment (closed, open, normal pressure, vacuum).

8. Overload protection, double protection and insulation, to give you security.

9. External stirring form: spiral belt scraping and stirring, which is more than 2/3 higher than ordinary efficiency;;

10. Internal stirring form: paddle stirring, which makes the flow of liquid more irregular, so as to achieve a good mixing effect.

11. The mixing structure adopts a fully welded method, the structure of the mixing pad is arranged at 45 degrees, and the joints are as far as possible to avoid the generation of a 90-degree angle.

12. A special type of frame-type wall scraping stirring device is adopted, and the stirring impact force is adjusted by a stepless frequency conversion speed regulator, and the speed can be adjusted arbitrarily within the speed range of 12-120 rpm. The steering turns clockwise from top to bottom, which can be adapted to the emulsification processing of various viscosity materials.

13. A special type of stainless steel discharge valve is matched to ensure that there is no dead corner at the bottom of the pot, which further improves the quality of homogenization and emulsification.

14. The speed reducer adopts the cycloidal pin wheel reducer and the lubricating oil adopts 2L-2 lithium base grease.

15. The body of the emulsification pot is a three-jacket structure, and the parts of the inner pot in contact with the materials are imported 304 and non-toxic and harmless materials to ensure the quality of the products. The outer layer is filled with thermal insulation cotton to reduce energy consumption. There is a sight glass and a vacuum sight glass with a scraper on the lid of the pot, a spice bucket, a filter, a vacuum pressure gauge, etc.

16. All functions such as heating, cooling, stirring, homogenization control buttons and temperature measuring instruments are concentrated on the control cabinet panel, which is convenient and reliable to operate.

17. This device is equipped with a hydraulic lifting system, electric lifting, easy to operate, can effectively emulsify the material under closed conditions, ordinary fixed does not have this lifting system.

18. The vacuum emulsifier introduces foreign technology and is professionally designed according to the creaming process of cosmetics and ointment products. This unit consists of a pretreatment pot, a vacuum homogenizing mixing pot, a vacuum pump, a hydraulic system, an electrical control system, and a working platform.

19. Spiral ribbon scraping and mixing can make the product easier to mix, and the mixing efficiency is at least 2/3 higher than that of ordinary frame mixing;

20. The homogenizing head is processed by a high-precision machining center to ensure high precision and dynamic balance requirements. With the same energy input, it can produce a finer emulsion of 2~5μm than the traditional gear ring disperser;

21. speed vacuum emulsifying mixing equipment is provided with oil pressure lifting system, which can freely lift and lower the boiler cover and has such functions as boiler tilting.

Technical parameter:

|

Model |

Capacity (L) |

Main pot power (kw) |

Oil water pot power (kw) |

Hydraulic lift power (kw) |

Total power(kw) |

||||||

|

Main tank |

Water tank |

Oil tank |

Mixing motor |

Homogenizer motor |

Mixing RPM |

Homogenizer RPM |

Steam heating |

Electrical heating |

|||

|

ZT-KB-150 |

150 |

120 |

75 |

1.5 |

2.2--4.0 |

0--63 |

0-3000 |

1.5 |

1.5 |

13 |

30 |

|

ZT-KB-200L |

200 |

170 |

100 |

2.2 |

42.2--5.5 |

1.5 |

1.5 |

15 |

40 |

||

|

ZT-KB-300 |

300 |

240 |

150 |

3.0--4.0 |

4.0--7.5 |

1.7 |

1.7 |

18 |

49 |

||

|

ZT-KB-500 |

500 |

400 |

200 |

3.0--4.0 |

7.5--11 |

2.2 |

2.2 |

24 |

63 |

||

|

ZT-KB-1000 |

1000 |

800 |

400 |

4.0--7.5 |

7.5--11 |

2.2 |

2.2 |

30 |

90 |

||

|

UP TO 3000 |

|

|

|||||||||

|

Remark: The machine dimensioon motor power can be customized according customers workshop |

|||||||||||

Application

Homogenization: medicine emulsion, ointment, cream, facial mask, cream, tissue homogenization, milk product homogenization, juice, printing ink, jam:

(1) Daily chemical and cosmetic industry: skin care cream, shaving cream, shampoo, toothpaste, cold cream, sunscreen, facial cleanser, nutritional honey, detergent, shampoo, etc.

(2), pharmaceutical industry: latex, emulsion, ointment (ointment), oral syrup, etc.

(3), food industry: thick sauce, cheese, oral liquid, baby food, chocolate, boil sugar, etc.

(4), chemical industry: latex, sauce, saponification products, paint, coatings, resins, adhesives, detergents, etc.

Option

1. power supply: three phase : 220v 380v .415v. 50HZ 60HZ

2. Capacity : 100L up to 5000L

3. Motor brand : ABB. Siemens option

4. Heating method: Electric heating and steam heating option

5. control system Key bottom for esay run

6. Fixed type or Hydraulic lifting type or Pneumatic lifting

7. variety of paddle designs meet difference requirement

8. SIP number is available upon request for cleaning process