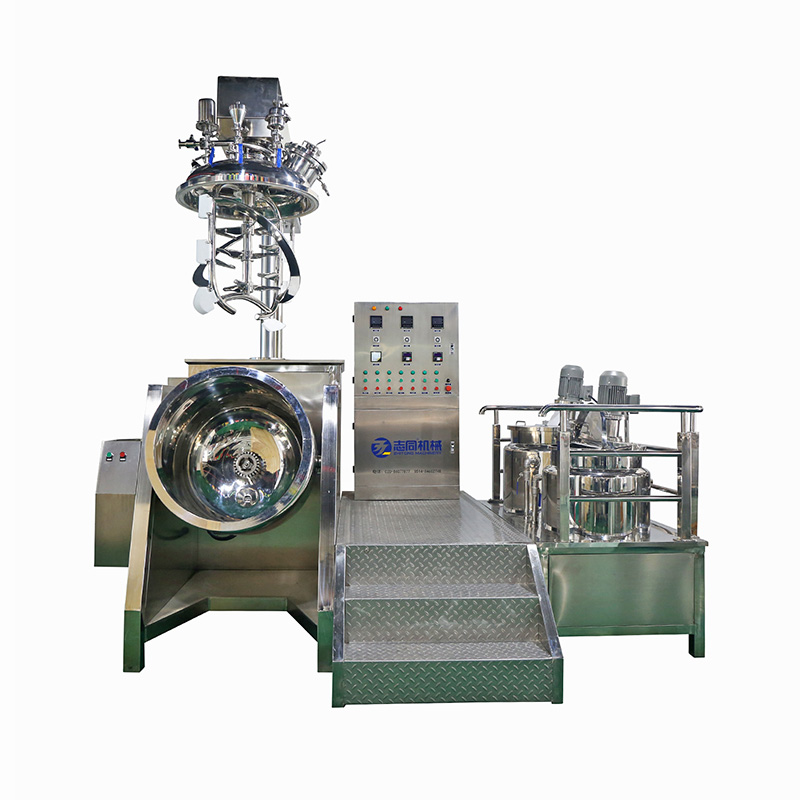

Product Description

8.emulsifying tshuabYuav nruab nrog: batching system, tso tawm qhov system, cua txias thiab cua sov tswj qhov system, lub tshuab nqus tsev, tiv thaiv nitrogen, PH tus nqi hauv online ntsuas kev tswj, CIP tu system, thiab lwm yam.

9. Lub tshuab nqus tsev ntawmemulsifying tshuabtshem tawm cov pa npuas thaum sib tov thiab hloov cov khoom xyaw;

3.Ideal zaus conversion ceev tswj ntaus ntawv yuav ua rau tus ceev arbitrary stepless ceev tswj.

10.Txawv lub tsho tsim muaj rau chav thiab hluav taws xob cua sov ntawmEmulsification tshuab

11. Emulsifier tshuabLub tshuab nqus tsev kom tshem tawm cov pa npuas thaum sib tov thiab hloov cov khoom xyaw;

12. Emulsifier tshuabQhov zoo tshaj plaws zaus hloov dua siab tshiab kev tswj cov cuab yeej tuaj yeem ua rau qhov nrawm nrawm nrawm nrawm nrawm.

13.Nqus Homogenizer Emulsifier Tov Khoom yog nruab nrog cov khoom siv tshwj xeeb pom iav ntawm lub hau ntawm lub lauj kaub, nruab nrog lub teeb pom kev zoo kaw;

14.Ob chav ntsuas kub probes thiab controllers rau hluav taws xob cua sov nyob rau hauv lub ntsiab emulsification tshuab;

15.Txhua qhov chaw sib cuag yog ua los ntawm SS316L thiab daim iav polished rauEmulsifier tshuab

16.Ntau yam kev tiv thaiv kev nyab xeeb rau lub tshuab nqus tsev, hydraulic twj tso kua mis thiab cov neeg ua haujlwm;

17.Cov khoom ntawm kev tiv tauj yog SUS316L stainless hlau, sab hauv thiab sab nraud ntawm cov khoom siv nrog iav polishing thiab tau txais GMP tus qauv.

18.Tag nrho cov kav dej thiab parameter yog tswj tsis siv neeg.Thiab cov khoom siv hluav taws xob uas tuaj ntawm txawv teb chaws, zoo li Siemens, Schneider thiab lwm yam.

19.Emulsifying tank txais tertiary agitating system, thiab thaum lub sij hawm emulsification, tag nrho cov txheej txheem yog nyob rau hauv lub tshuab nqus tsev ib puag ncig, yog li nws tsis tsuas yog yuav tshem tawm spume uas tsim nyob rau hauv lub emulsification processing, tab sis kuj yuav zam qhov tsis tsim nyog cov pa phem.

20.Homogenizer txais yuav cov cuab yeej siv siab tshaj plaws, nws tuaj yeem tau txais cov txiaj ntsig zoo tshaj plaws emulsifying.Qhov ceev ntawm emulsification siab yog 0-3500r / min, thiab qhov ceev ntawm qhov sib tov yog 0-63r / min.

21.Lub tshuab nqus tsev emulsifying tov khoom yog tsim los ntawm lub lauj kaub dej, roj lauj kaub, emulsifying lauj kaub, lub tshuab nqus tsev, lifting system (yeem), hluav taws xob tswj system (PLC yog xaiv tau).kev lag luam platform, thiab lwm yam muaj peev xwm ua tau customized.

22.Polytetrafluroethylene scraping board cater rau lub cev ntawm kev sib xyaw zawj thiab khawb tawm cov khoom viscosity ntawm boiler.

23.txais yuav cov kws kho tsheb txawv teb chaws los xyuas kom ntseeg tau tias muaj kev ruaj ntseg ntev lub neej foob thiab txuag cov nqi seem.

24. Emulsifier tshuabmuaj Ob lub tsho rau cua sov thiab cua txias;Agitating system muaj lub qhov rais thiab lub teeb.

19.Kev sib xyaw motors txais yuav Siemens lossis ABB hom ua kom lub tshuab muaj kev ua tau zoo dua thiab tsis muaj suab nrov.

25.Emulsifier tov khoomcov lus qhia tshwj xeeb ntawm lub tshuab nqus tsev homogenization ua raws li GMP cov cai;

26.1440rpm disperser nyob rau hauv cov roj tank thiab dej tank, nrog cua sov muaj nuj nqi kom yaj raw khoom sai sai.

27.Mightiness tshuav nyiaj li cas isotactic nkhaus rotor yog txuam nrog stator nrog cov qauv coj kom paub txog cov kua muaj peev xwm txiav, txhuam;

28. tshuab nqus tsev cosmetic cream ua tshuabincorperates lub ntse tswj system thiab siab tsis siv neeg thiab yooj yim neeg siv interface;

29.Roj hydraulic lifting system kom yooj yim tu thiab tu thiab yooj yim los xyuas cov tso tsheb hlau luam hauv;

30. Tshuaj pleev ib ce Emulsifiermuaj Spray pob yog nruab los txuas rau cov neeg siv khoom CIP system rau kev ntxuav tsis siv neeg.

Technical parameter:

| Qauv | Peev xwm (L) | Lub zog loj (kw) | Roj av lub hwj chim (kw) | Hydraulic nqa lub zog (kw) | Tag nrho lub zog (kw) | ||||||

| Lub tank loj | Lub tank dej | Roj tank | Sib tov lub cev muaj zog | Homogenizer lub cev muaj zog | sib tov RPM | Homogenizer RPM | Chav cua sov | Hluav taws xob cua sov | |||

| ZT-KB-50 | 50 | 40 | 25 | 1.1 | 2.2 | 0-63 ib | 0-3000 | 0.75 ib | 0.75 ib | 9 | 18 |

| ZT-KB-150 | 150 | 120 | 75 | 1.5 | 4--9 | 1.5 | 1.5 | 13 | 30 | ||

| ZT-KB-200L | 200 | 170 | 100 | 2.2 | 4.0—11 | 1.5 | 1.5 | 15 | 40 | ||

| ZT-KB-300 | 300 | 240 | 150 | 2.5 | 4.0—11 | 1.7 | 1.7 | 18 | 49 | ||

| ZT-KB-500 | 500 | 400 | 200 | 4 | 5.0—11 | 2.2 | 2.2 | 24 | 63 | ||

| ZT-KB-1000 | 1000 | 800 | 400 | 5.5 | 7.5—11 | 2.2 | 2.2 | 30 | 90 | ||

| Mus txog 3000 | |||||||||||

| Lus Cim: Lub tshuab dimensioon lub cev muaj zog tuaj yeem ua raws li cov neeg siv khoom rhiav | |||||||||||

Daim ntawv thov

Homogenization: tshuaj emulsion, tshuaj pleev, qab zib, lub ntsej muag daim npog qhov ncauj, cream, ntaub so ntswg homogenization, mis nyuj khoom homogenization, kua txiv, luam ntawv number case, jam:

1. zoo tshuaj: yas, fillers, nplaum, resins, silicone roj, sealants, slurry, surfactants, carbon dub, colloid zeb, emulsifying tshuab, lim defoaming tus neeg saib xyuas, brightener, tawv additives, coagulants, thiab lwm yam.

2. kev lag luam tshuaj txhua hnub: ntxuav cov hmoov, tshuaj ntxuav tes, tshuaj ntxuav tes, txhua yam tshuaj pleev ib ce, kev tu tawv nqaij.

Kev xaiv

1.Fais fab mov: peb theem: 220v 380v .415v.50HZ 60HZ

2.Muaj peev xwm: 50L txog 500L

3.Lub cev muaj zog: ABB.Siemens kev xaiv

4.Cov txheej txheem cua sov: hluav taws xob cua sov thiab chav cua sov xaiv

5.tswj qhov system plc kov npo.Ntsiab hauv qab

6.Tsau hom lossis Hydraulic lifting hom lossis Pneumatic lifting

7.ntau yam paddle designs raws li qhov yuav tsum tau sib txawv

8.SIP muaj nyob rau ntawm kev thov rau kev ntxuav

-

1L10L Laboratory Homogenizer Tov Khoom Lab Nqus E...

-

Hydraulic lub tog raj kheej emulsion tov khoom tshuabI Cosm ...

-

Hluav taws xob cua sov nqus emulsifying equipmen ...

-

Hydraulic lifting hom nqus emulsifier | Vacuu ...

-

Muab Customize homogenizer Tov Tank indus ...

-

Lab nqus emulsifier | Homogenizer Rau Tshuaj pleev ib ce