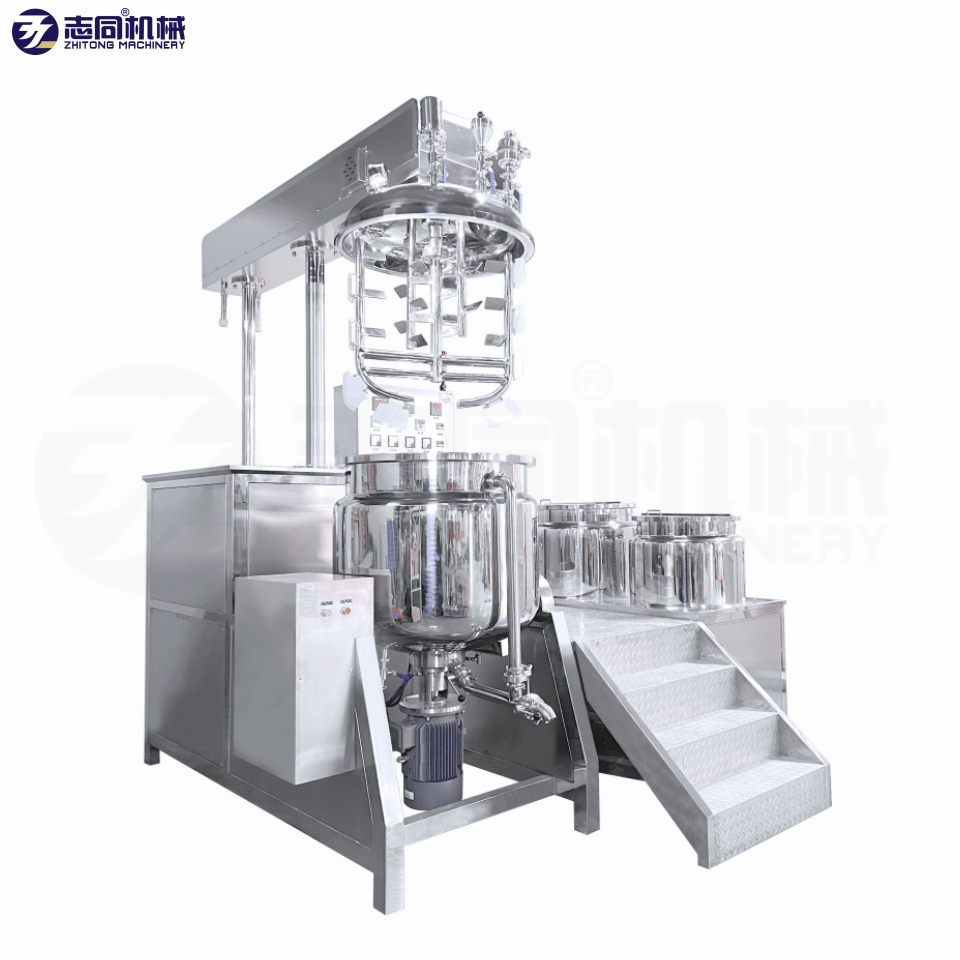

Product Description

1.tshuaj pleev ib ce tov khoomyog ib qho yooj yim rau kev khiav lag luam, ruaj khov nyob rau hauv kev ua tau zoo, zoo nyob rau hauv homogenization, siab nyob rau hauv ntau lawm efficiency, yooj yim los ntxuav, tsim nyog nyob rau hauv cov qauv, me me nyob rau hauv cheeb tsam, thiab siab nyob rau hauv automation.

2. Sab hauv thiab sab nraud ncig homogenization ntawmtshuaj pleev ib ce tov khoomnrog siab dua homogenization efficiency.

3. tshuaj pleev ib ce tov khoomTau txais lub teb chaws cov tswv yim thiab zoo li patents, lub teb chaws high-tech khoom;

4.Lub hau ntawmtshuaj pleev ib ce tov khoomyog hydraulic / hluav taws xob lifting hom, thiab txoj kev tso tawm yog lub emulsification lauj kaub lub cev yog qaij los yog hauv qab yog pressurized thiab cov khoom yog tawm nrog lub twj tso kua mis.Txoj kev kho zoo tshaj plaws tuaj yeem xaiv raws li cov khoom sib txawv.

5. Homogenizer emulsifier tov khoomnrog ceev lub tshuab nqus tsev emulsifying sib tov khoom nrog roj siab lifting system, uas muaj peev xwm nqa tau dawb thiab txo lub boiler thiab muaj xws li lub zog xws li boiler tilting.

6.Lub tshav kub conduction nruab nrab nyob rau hauv lub tsho ntawmHomogenizer emulsifier tov khoomrhuab los ntawm hluav taws xob cua sov raj kom paub qhov cua sov ntawm cov khoom.

7.Cov cua kub kub tuaj yeem teem caij arbitrarily thiab tswj tau.Nws tuaj yeem ua kom sov los ntawm chav.

8.Lub foob ntawmHomogenizer emulsifier tov khoomadopts ib tug tshwj xeeb tsim ob chav kawg lub ntsej muag mechanical foob thiab ib tug thib ob foob ntawm lub cev pob txha roj foob, thiab cov neeg kho tshuab foob txais cov dej txias circulating txias.

9.sab sauv sealing ntaus ntawv ntawmHomogenizer emulsifier tov khoomadopts ib-kawg mechanical seal (cov kua sealing adopts glycerin).

10.Lub lauj kaub yaj tau teeb tsa raws li cov neeg siv khoom xav tau rau cov roj thiab dej, thiab lub tsho cua sov chav valve yog manually ua.Hluav taws xob cua sov ua kom lub cua sov khawm.Sab saum toj ntsug high-shear homogenizing emulsifier lossis cov khoom sib xyaw zoo tib yam heats pub tusyees.

11.Cov dej txias tuaj yeem txuas nrog lub tsho kom txias cov khoom.

15. Homogenizer emulsifier tov khoomKev khiav hauj lwm yooj yim thiab yooj yim, nrog ib txheej rwb thaiv tsev sab nraum mezzanine.

16.Lub foob ntawm lub homogenization ntaus ntawv txais yuav ib tug tshwj xeeb tsim ob kawg lub ntsej muag mechanical foob thiab ib tug thib ob foob ntawm lub cev pob txha roj foob, thiab cov neeg kho tshuab foob txais cov dej txias circulating txias.

17.lub cev muaj zog ceev ntawmHomogenizer emulsifier tov khoomtuaj yeem tswj tau los ntawm tus tswv xeev zaus hloov dua siab tshiab los ntawm cov khoom siv hloov pauv hloov ceev ceev kom tau raws li qhov nrawm nrawm thiab muaj zog torque.

Technical parameter:

| Qauv | Peev xwm (L) | Lub zog loj (kw) | Lub zog hluav taws xob (kw) | Hydraulic zog (kw) | Tag nrho lub zog (kw) | ||||||

|

| Lub tank loj | Lub tank dej | Roj tank | Sib tov lub cev muaj zog | Homogenizer lub cev muaj zog | Mixing RPM | Homogenizer RPM |

|

| Chav cua sov | Hluav taws xob cua sov |

| ZT-KB-150 | 150 | 120 | 75 | 1.5 | 2.2-4.0 Nws | 0—63 ib | 0-3000 | 1.5 | 1.5 | 13 | 30 |

| ZT-KB-200L | 200 | 170 | 100 | 2.2 | 4.2-5.5 | 1.5 | 1.5 | 15 | 40 | ||

| ZT-KB-300 | 300 | 240 | 150 | 3.0 - 4.0 | 4.0-7.5 Nws | 1.7 | 1.7 | 18 | 49 | ||

| ZT-KB-500 | 500 | 400 | 200 | 3.0 - 4.0 | 7.5—11 | 2.2 | 2.2 | 24 | 63 | ||

| ZT-KB-1000 | 1000 | 800 | 400 | 4.0-7.5 Nws | 7.5—11 | 2.2 | 2.2 | 30 | 90 | ||

| Txog li 3000 |

|

|

|

| |||||||

| Lus Cim: Lub tshuab dimensioon lub cev muaj zog tuaj yeem ua raws li cov neeg siv khoom rhiav | |||||||||||

Daim ntawv thov

Homogenization: tshuaj emulsion, tshuaj pleev, qab zib, lub ntsej muag daim npog qhov ncauj, cream, ntaub so ntswg homogenization, mis nyuj khoom homogenization, kua txiv, luam ntawv number case, jam:

(1) Kev lag luam tshuaj thiab tshuaj pleev ib ce txhua hnub: tshuaj pleev ib ce, shaving cream, tshuaj zawv plaub hau, tshuaj txhuam hniav, tshuaj pleev ib ce, tshuaj pleev thaiv hnub, tshuaj ntxuav lub ntsej muag, khoom noj khoom haus zib ntab, xab npum, tshuaj zawv plaub hau, thiab lwm yam.

(2) Kev lag luam kws tshuaj: latex, emulsion, tshuaj pleev (ointment), qhov ncauj syrup, thiab lwm yam.

(3) kev lag luam khoom noj khoom haus: kua ntses tuab, cheese, kua hauv qhov ncauj, khoom noj me nyuam mos, chocolate, boil qab zib, thiab lwm yam.

(4) chemical kev lag luam: latex, sauce, saponification khoom, xim, coatings, resins, adhesives, detergents, thiab lwm yam.

Kev xaiv

1.Fais fab mov: peb theem: 220v 380v .415v.50HZ 60HZ

2.Muaj peev xwm: 100L txog 3000L

3.Lub cev muaj zog: ABB.Siemens kev xaiv

4.Cov txheej txheem cua sov: hluav taws xob cua sov thiab chav cua sov xaiv

5.tswj qhov system plc kov npo.Ntsiab hauv qab

6.Tsau hom lossis Hydraulic lifting hom lossis Pneumatic lifting

7.ntau yam paddle designs raws li qhov yuav tsum tau sib txawv

8.SIP muaj nyob rau ntawm kev thov rau kev ntxuav

Video

-

Nqus Homogenizer Emulsifier | Tshuaj pleev ib ce Homogeni ...

-

Ob chav hydraulic kheej kheej emulsion tov khoom tshuab ...

-

Sab hauv thiab sab nraud ncig emulsifying m...

-

Hydraulic nqa lub tshuab nqus tsev emulsifier mixing mach ...

-

Ntsiab hauv qab mixer emulsifier rau cosmetic ua ...

-

Lab nqus emulsifier | Homogenizer Rau Tshuaj pleev ib ce