Video

1. Siemens touch PLC operating system

2.tanks material . inner layer SS 316. Middle and out layer SS304

3.Motor brand: AAB OR Siemens

4.Heating method : steam heating or electrical heating or no heating

5.power supply : three phase 220voltage 380voltage 460voltage 50HZ 60HZ for option

6.leader time 30 days

7. Compliance with GMP rules

8.simple and convenient operation, insulation layer outside layer and keep operator safety

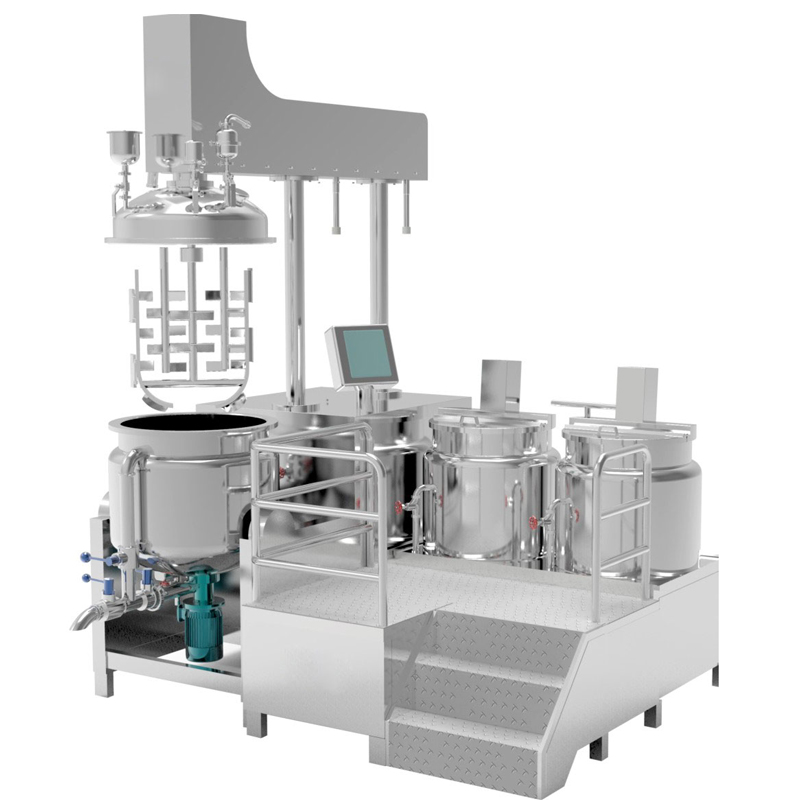

9.The key emulsification motor can be combined with different hoppers, pretreatment reactors and discharge buffer tanks depending on making processing .

the homogeneous motor can be frequency conversion speed regulation, low speed 3000 RPM for low speed homogenization, high speed 6000 RPM for high speed homogenization. For large range taste product

10.It integrates inhalation, transport, dispersion, and CIP online cleaning.

the powerful pumping capacity and the ability to deliver highly viscous materials.

11.CIP cleaning system is configured through the external circulation pipeline to achieve automatic cleaning, convenience and sanitation of emulsifying machine.

allows the aqueous phase and the oil phase to be emulsified directly in the homogenization system,

12.The modular design of the tie rod is convenient for maintenance and disassembly.

More choice of whether the material will pass through the emulsification chamber.

system electronic control unit can be configured with simple button control or a PLC touch screen system with recipe control,

13.Adopted PLC and Siemens touch screen HMI. Making the operation is more simple .

remove bubble occur under low temperature and vacuum status and high viscosity condition less air bubble will be formed.no Oxidation products

14.Adopting imported 316L stainless steel materials, inside and outside polishing, conforming to GMP standards

SIP system an ideal device for cleaning processing . flexible in design and can be customized according to the needs of capacity and client need .

15.Variable speed for homogenizer1-3000R/min and agitator 1-63R/min;

16.Fixed paddle(ss316) and wall scraper (food grade material) mixing system.

17Complete process of mixing, dispersing, emulsifying, homogenizing, vacuum, heating and cooling in one unit

circulation line can directly pass steam to heat the material. More efficient is our constant pursuit.

Technical parameter:

| Model | Capacity(L) | Emulsify motor | Mixing motor | Toal power(steam/electric heating ) | Limited vacuum (Mpa) | Size (mm)L*W*H | ||||

| Main pot | Oil pot | Water pot | KW | RPM | KW | RPM | ||||

| 100 | 100 | 50 | 80 | 4 | 0--3000 | 1.5 | 0-63 | 10/37 | -0.095 | 2385*2600*200-2900 |

| 200 | 200 | 100 | 160 | 5.5 | 2.2 | 12/40 | 2650*3000*2400-3100 | |||

| 500 | 500 | 250 | 400 | 11 | 4 | 18/63 | 3400*3500**3900 | |||

| 1000 | 1000 | 500 | 800 | 15 | 5.5 | 30/90 | 3600*4200*4600 | |||

| 2000 | 2000 | 1000 | 1600 | 18 | 7.5 | 40/120 | 4200*4800*5400 | |||

Option

1.power supply: three phase : 220v 380v .415v. 50HZ 60HZ;

2.Capacity : 100L up to 5000L;

3.Motor brand : ABB. Siemens option;

4.Heating method: Electric heating and steam heating option;

5.control system plc touch screen. Key bottom;

6.Fixed type or Hydraulic lifting type or Pneumatic lifting;

7.variety of paddle designs meet difference requirement;

8.SIP is available upon request for cleaning process.