Product Description

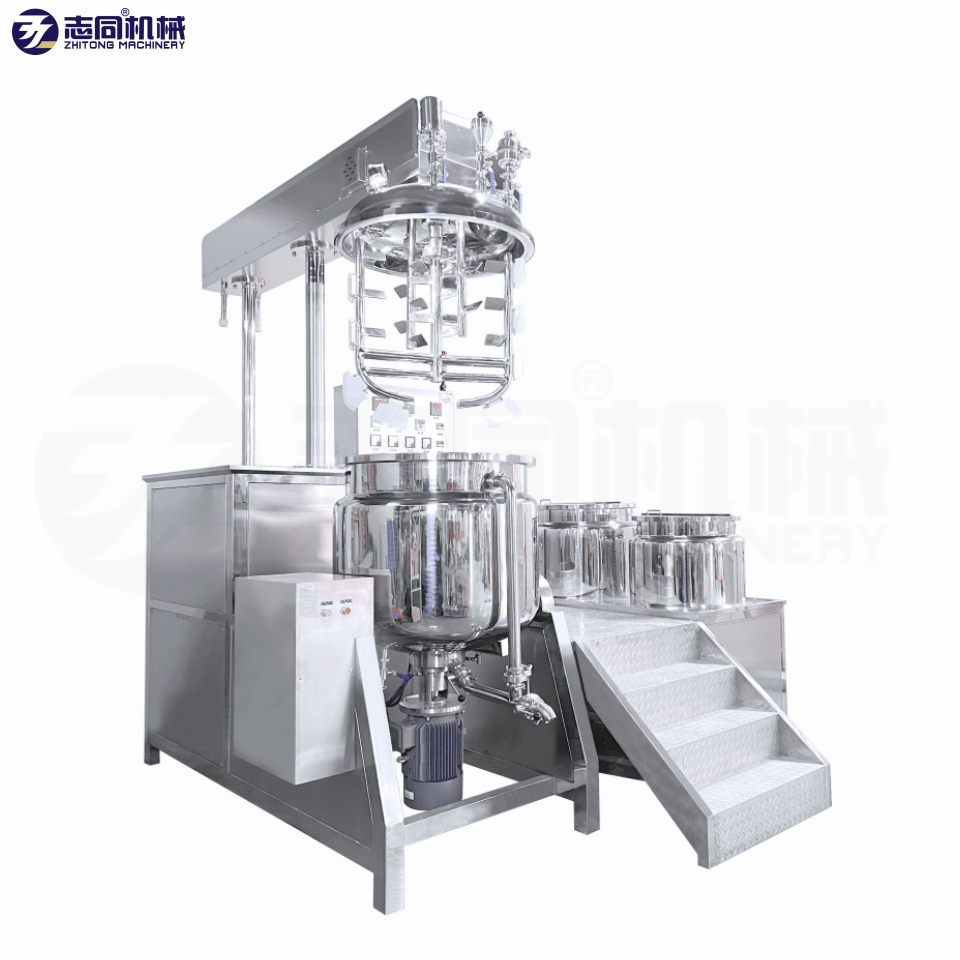

1. Vacuum Homogenizer Emulsifier

Lifting emulsifier, including emulsifying pot , operating platform, oil and water pot , oil and water pot and controller; Emulsifying pot device including emulsifying pot, emulsifying pot rack and emulsifying pot cover fixed plate, emulsifying pot set on mixing mechanism, dumping, cooling circulation mechanism, vacuum institutions and emulsifying pot cover lifting mechanism, mixing, dumping, cooling cycle machine, vacuum institutions and emulsifying pot cover the controlled end of the lifting mechanism is connected to the output of the controller.

2. Working capacity from 10L up to 200L;

3. Cosmetic Homogenizer stair Anti-skip Stainless steel platform for operator safety

4. Suitable for high viscosity material of 10,000~120,000cps viscosity;

5. Contra mixing system of fixed impellers with holes and wall scraper

6. Perfect particle size of 2 micrometers and evenly distributed;

7. Vacuum Mixer Machine Vacuum function defoaming can make the materials meet the requirement of being aseptic.

8. SS304/316 material. Long service life and import brand component.

9. Vacuum Mixer Homogenizer Vacuum system to take out the air bubbles during mixing and to transfer the ingredients.

10. Adopts 3 layers double jacket design, with heating and cooling function.

11. The stirring paddle with scraper, so that the products attached on the inner wall can be scrapered off and making the products mixing well.

Technical parameter:

|

Model |

Capacity (L) |

Main pot power (kw) |

Oil water pot power (kw) |

Hydraulic lift power (kw) |

Vacuum pump power |

Total power(kw) |

||||

|

Main tank |

Water tank |

Oil tank |

Mixing motor |

Homogenizer motor |

Steam heating |

electrical heating |

||||

|

RHJ- KB10L |

10L |

8 |

5 |

0.37 |

1.1 |

0.15 |

0.55 |

0.55 |

3 |

6 |

|

RHJ-KB20L |

20L |

18 |

10 |

0.55 |

1.5 |

0.15 |

0.75 |

0.75 |

3 |

6 |

|

RHJ-KB30L |

30L |

25 |

15 |

0.75 |

2.2 |

0.15 |

0.75 |

0.75 |

9 |

18 |

|

RHJ-KB50L |

50L |

40 |

25 |

0.75 |

3-7.5 |

0.75 |

1.1 |

1.5 |

13 |

30 |

|

RHJ-KB100L |

100L |

80 |

50 |

1.5 |

4-7.5 |

1.1 |

1.1 |

1.5 |

14 |

32 |

|

RHJ-KB200L |

200L |

170 |

100 |

3 |

5.5-11 |

1.5 |

1.5 |

2.2 |

15 |

40 |

|

Remark: The machine dimensioon motor power can be customized according customers workshop |

|

|||||||||

Application

Mixing: syrups, shampoos, detergents, skincare .cream products , yogurt, desserts, mixed dairy products, ink, enamel.

Homogenization: medicine emulsion, ointment, cream, facial mask, cream, tissue homogenization, milk product homogenization, juice, printing ink, jam

Skin care cream, shaving cream, shampoo, toothpaste, cold cream, sunscreen, facial cleanser, nutritional honey, detergent, shampoo, etc.

Option

1. Vacuum Mixer Homogenizer

power supply: three phase : 220v 380v .415v. 50HZ 60HZ

2. Capacity : 10L up to 100L

3. Motor brand : ABB. Siemens option

4. Heating method: Electric heating and steam heating option

5. Vacuum Mixer Homogenizer control system plc touch screen. Key bottom

6. Hydraulic lifting type or Pneumatic lifting

7. variety of paddle designs meet difference requirement

8. SIP spray ball No is available upon request for cleaning process of Vacuum Mixer Homogenizer