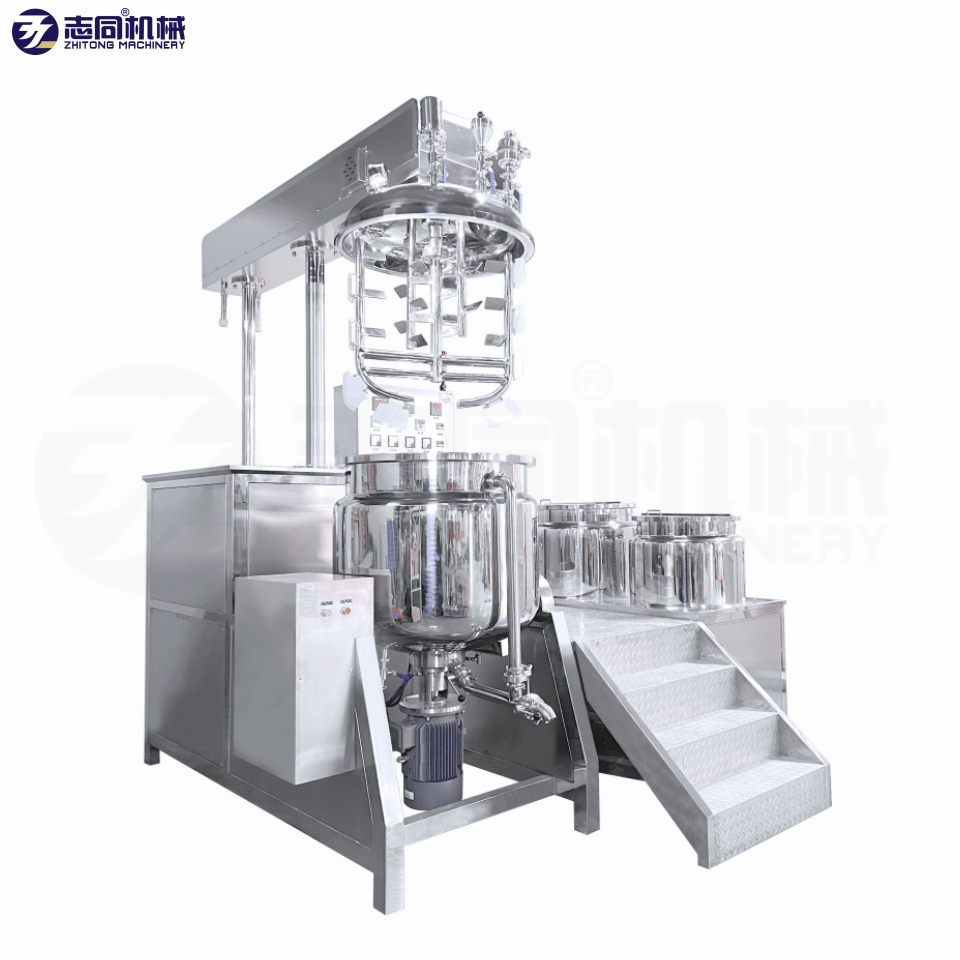

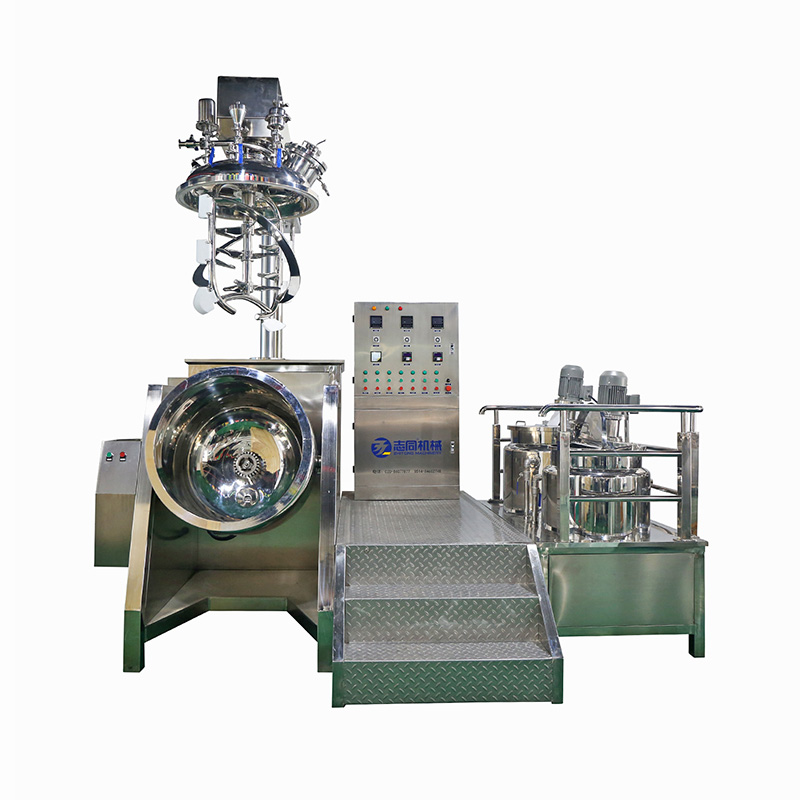

Product Description

1.CovCosmetic Manufacturing Equipmentadopts lifting system, yooj yim los ntxuav nrog CIP pob thiab cov nyhuv tu yog ntau abvious, lub lauj kaub emulsifying tuaj yeem txais tilting paug

2.Haum rau qab zib thiab emulsion ntawm 10,000 ~ 180,000cps viscosity

3.Lub homogenizer thiab cov hniav nplawm tuaj yeem ua ke ua haujlwm lossis cais ua haujlwm

4.Qhov noCosmetic Manufacturing Equipmentlub tshuab nqus tsev tov khoom siv lub tshuab nqus tsev twj tso kua mis txais ob-txoj kev phab ntsa scraping blending thiab zaus hloov pauv hloov ceev kom ua tau raws li cov kev cai sib txawv.

5.Nrog adopts lifting system, yooj yim los ntxuav nrog CIP pob thiab cov nyhuv ntxuav yog ntau abvious rauCosmetic Manufacturing Equipment, lub lauj kaub emulsifying tuaj yeem txais tilting paug.

6. Cov khoom siv tshuaj pleev ib ce yogHaum rau qab zib thiab emulsion ntawm 10,000 ~ 180,000cps viscosity.

7.Lub homogenizer thiab cov hniav nplawm tuaj yeem ua ke ua haujlwm lossis cais ua haujlwm.

8.Scraping unit yog nrog txav tau teflon scrapers los txhuam tawm cov ntaub ntawv ntawm lub tank phab ntsa thiab lub thauj tog rau nkoj kom txav cov ntaub ntawv mus rau qhov chaw nruab nrab kom tau zoo sib xyaw thiab sib tov.Cov teflon scrapers tau tuav manually thiab yooj yim tsis muaj cuab yeej.

9.Txhua qhov chaw sib cuag ntawm cov khoom siv yog SUS316L, cov khoom lag luam homogenized hauv lub tshuab nqus tsev thiab lub nkoj kaw tuaj yeem ua kom huv thiab zoo.

10.Polytetrafluroethylene scraping board cater rau lub cev ntawm kev sib xyaw zawj thiab khawb tawm cov khoom viscosity ntawm phab ntsa boiler;

11. Cosmetic Manufacturing Equipmentmuaj homogenizer kuj ua haujlwm raws li lub twj tso kua mis hloov mus rau cov khoom tiav;Txuag ib lub twj tso kua mis rau kev siv nyiaj;

12.Cov specificationsCosmetic Manufacturing khoomua raws li GMP cov cai;

13.Multi-layer rotor ua rau lub zog nqus dej kom nqus cov khoom rau hauv cov kab noj hniav ua haujlwm.

14.Cosmetic tov khoomlifting yog yooj yim rau homogenous nyob rau hauv qhov chaw kaw thiab ua rau lub tshuab nqus tsev theem (-0.095mpa).

15.centrifugal kom paub tseeb tias zoo nkauj thiab slick qab zib;Boiler lub cev thiab cov yeeb nkab saum npoo iav polishing 300EMSH (qib huv huv) ua raws li Kev Cai Txhua Hnub thiab GMP kev cai.

16.Ua kom tiavCosmetic Mixertxheej txheem ntawm kev sib tov, dispersing, emulsifying, homogenizing, nqus tsev, cua sov thiab txias hauv ib chav tsev kom yooj yim rau kev khiav lag luam.

17.45 degree inclined hniav, xyuas kom cov khoom dov thiab nplawm cov nyhuv Seamless vuam, yooj yim dua los ntxuav tom qab ntau lawm rau kev ua haujlwm zoo ntawm lub tshuab.

18.khawm tswj vaj huam sib luag rau kev ua haujlwm yooj yim thiab raug nqi qis.

19.Ob chav ntsuas kub probes ntawmCosmetic Mixerthiab controllers rau hluav taws xob cua sov nyob rau hauv lub ntsiab emulsifying tov khoom;

20.cov khoom yog nyob rau hauv lub nqus tsev vacuum thaum lub sij hawm tag nrho cov txheej txheem ntau lawm nyob rau hauv lubCosmetic Mixer, ua cov khoom zoo thiab tsis muaj npuas.

21.Kev sib xyaw ua ke ntawm lub tshuab nqus tsev emulsifying tov khoom siv cov khoom siv sib xyaw ua ke siab heev thiab kev hloov pauv zaus hloov pauv, yog li kev tshaj tawm kom txaus siab rau kev tsim cov tshuab sib txawv.

22Lub stator thiab rotor ntawm lub taub hau homogenous yog nruj ua ke, 1-2 hli.Ib zaug casting los ua kom tiav cov pwm.

Technical parameter:

| Qauv | Peev xwm (L) | Lub zog loj (Kw) | Roj av lub hwj chim (Kw) | Hydraulic nqa lub zog (Kw) | Tag nrho lub zog (kw) | ||||||

|

| Lub tank loj | Lub tank dej | Roj tank | Sib tov lub cev muaj zog | Homogenizer lub cev muaj zog | sib tov RPM | Homogenizer RPM |

|

| chav cua sov | Hluav taws xob cua sov |

| ZT-KB-150 | 150 | 120 | 75 | 1.5 | 2.2-4.0 Nws | 0-63 ib | 0-3000 | 1.5 | 1.5 | 13 | 30 |

| ZT-KB-200L | 200 | 170 | 100 | 2.2 | 2.2-5.0 Nws | 1.5 | 1.5 | 15 | 40 | ||

| ZT-KB-300 | 300 | 240 | 150 | 2.5 | 4.0—11 | 1.7 | 1.7 | 18 | 49 | ||

| ZT-KB-500 | 500 | 400 | 200 | 4 | 5.0—11 | 2.2 | 2.2 | 24 | 63 | ||

| ZT-KB-1000 | 1000 | 800 | 400 | 5.5 | 7.5—11 | 2.2 | 2.2 | 30 | 90 | ||

| Txog li 3000 |

|

|

|

| |||||||

| Lus Cim: Lub tshuab dimensioon lub cev muaj zog tuaj yeem ua raws li cov neeg siv khoom rhiav | |||||||||||

Daim ntawv thov

Homogenization: tshuaj emulsion, tshuaj pleev, qab zib, lub ntsej muag daim npog qhov ncauj, cream, ntaub so ntswg homogenization, mis nyuj khoom homogenization, kua txiv, luam ntawv number case, jam:

Khoom noj khoom haus kev lag luam: chocolate plhaub, txiv hmab txiv ntoo pulp, mustard, slag ncuav mog qab zib, zaub xam lav, dej qab zib, txiv nkhaus taw, txiv lws suav pulp, qab zib tov, zaub mov essence, additives, thiab lwm yam.

8, nanomaterials: nano calcium carbonate, nano coatings, txhua yam nano khoom additives, thiab lwm yam.

Kev xaiv

1.Fais fab mov: peb theem: 220v 380v .415v.50HZ 60HZ

2.Muaj peev xwm: 100L txog 5000L

3.Lub cev muaj zog: ABB.Siemens kev xaiv

4.Cov txheej txheem cua sov: hluav taws xob cua sov thiab chav cua sov xaiv

5.tswj qhov system plc kov npo.Ntsiab hauv qab

6.Tsau hom lossis Hydraulic lifting hom lossis Pneumatic lifting

7.ntau yam paddle designs raws li qhov yuav tsum tau sib txawv

8.SIP muaj nyob rau ntawm kev thov rau kev ntxuav

Video

-

Hydraulic nqa lub tshuab nqus tsev emulsifier mixing mach ...

-

Hydraulic lifting hom nqus emulsifier | Vacuu ...

-

Yooj yim hom tshuaj pleev ib ce tov tshuab

-

Nqus Homogenizer Emulsifier | Tshuaj pleev ib ce Homogeni ...

-

1L10L Laboratory Homogenizer Tov Khoom Lab Nqus E...

-

Hluav taws xob cua sov nqus emulsifying equipmen ...